|

|

|

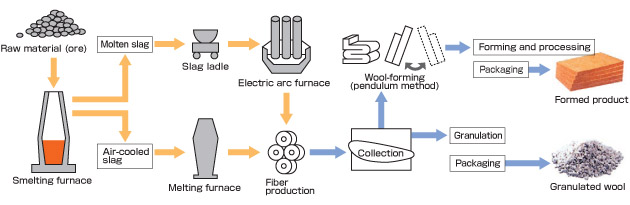

Blast furnace slag and other materials are either heated and re-melted in a cupola or electric arc furnace at 1,500 - 1,600℃ , or else after being removed from the blast furnace the molten slag is kept at approximately the same high temperature and is allowed to flow out from the bottom of the furnace. The molten slag is then blown to form fibers by centrifugal force or similar means. The fibrous rock wool is collected in a collection chamber. The process to create the final product differs depending on the application. To create “granulated wool,” the rock wool is separated and granulated. To create “formed products” such as board or mat shapes for housing applications, binder is added to the wool and it is hardened in a curing oven and adjusted to a fixed density and thickness.

Rock wool manufacturing process |

|

Rock wool and cross-sectional diagram |

|

Examples of rock wool applications |

|

|

|

|